Compact dry powders are used in our daily lives—they are used to create pharmaceutical tablets, detergent tablets, cosmetics, and candy. Production of a compact powder often begins with cold compaction to achieve powder cohesion through mechanical densification. Mechanical densification is governed by particle rearrangement, and elastic and plastic deformation. This initial compaction provides the powder with sufficient strength to withstand further manufacturing operations and handling.

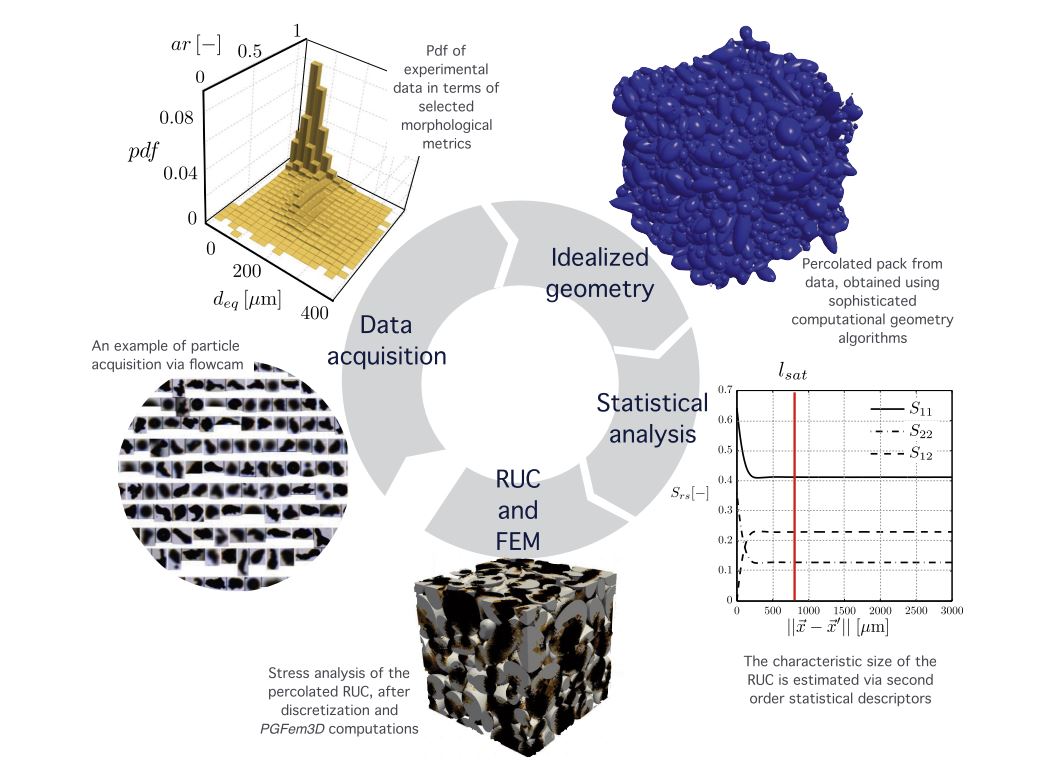

Pictured above: Infographic of the particle analysis and compact simulation methods used by Salvadori et al. (2017).

Enter Salvadori et al.

Young's modulus is a measure material rigidity or elasticity. In the article "Numerical and experimental analysis of the Young's modulus of cold compacted powder materials" published in the June issue of Mechanics of Materials, Salvadori et al. sought to estimate the Young's modulus of cold compacted metal powders by imaging the microstructure of aluminum powder and computing morphological reconstructions.

Microstructure analysis that does not use X-Rays

Micro-computed tomography (micro-CT) is a common, X-ray-based method for microstructure analysis for compacted powders. However, X-rays do not penetrate metals easily and therefore Salvadori et al. used the FlowCam to image the particles and the particle packing simulation software Rocpack to construct 3D analyses of particle compaction using their morphological data.

Prolate or Oblate? Using the FlowCam for particle analysis

2.5 g of aluminum powder was suspended in 500mL of 5% polyvinylpyrrolidone-deionized water and sonicated for 30 minutes. Using 4X objective and a 1mL flow cell, the suspension was imaged using the FlowCam and a 2D projection of each particle was obtained with two semi-axes a and b. Each particle was then further idealized as a 3D ellipse with a third semi-axis c. All particles were then categorized as either prolate (a>b=c) or oblate (a=c>b).

Percolation path determination using particle packing simulators

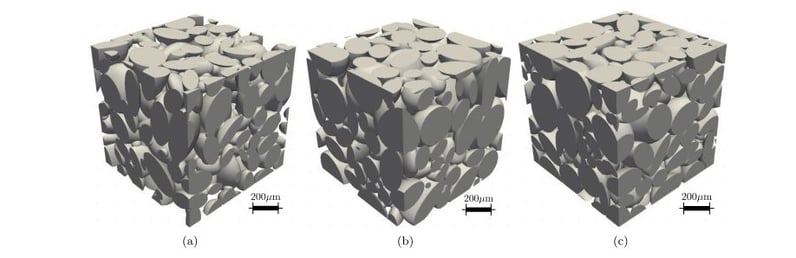

Salvadori et al. used the prolate to oblate ratio to simulate the percolation path of particles within a representative unit cell. Salvadori et al. computed a domain (in this case, a cube) in Rocpack, and filled it with the ratio of oblate to prolate particles as determined by the FlowCam analysis. The particles are placed in the cube as points and are randomly assigned oblate or prolate status. The particles are given random velocities and grow at a specified rate. As the particles grow, they collide and rearrange themselves to fill the volume of the cube until the specified densities reach 65%, 70% and 75%. The percolation paths of the particles and the interconnections between the particles within the domain were then calculated by Salvadori et al.

Rocpack particle percolation simulations at densities of 65% (a) 70% (b) and 75% (c). Image from Salvadori et al. (2017).

Calculate Young's Modulus? Learn more

To read more about how Salvadori et al. calculated the Young's modulus of cold compacted metal powders using the FlowCam and computational simulations, you can read the abstract and access the article here.

References:

Salvadori, A., Lee, S., Gillman, A., Matous, K., Shuck, C. Mukasyan, A., Beason, M.T., Gunduz, I.E., Son, S.F. (2017) Numerical and experimental analysis of the Young's modulus of cold compacted powder materials. Mechanics of Materials. doi: 10.1016/j.mechmat.2017.05.010